Alliance Dynamics | International Advanced Level! Another new technology of Jiangsu Sunshine passed the appraisal

On November 4, Jiangsu Sunshine Co., Ltd., Anhui Fengyuan Biofiber Co., Ltd. and Donghua University jointly undertook the "Key Technology and Industrialized Application of Wool Cashmere Polylactic Acid Fiber Series Fabrics", which passed the project appraisal organized by China Textile Industry Federation. The expert group composed of China Textile Industry Federation, China Wool Textile Industry Association, Shanghai Textile Science Research Institute, Jiangnan University, Nantong University and other institutions agreed that the technical project focused on the research and development of high-strength and soft polylactic acid fiber preparation technology and equipment suitable for wool and cashmere, and the two-stage variable speed heating dyeing process of polylactic acid fiber,

11month4Jointly undertaken by Jiangsu Sunshine Co., Ltd., Anhui Fengyuan Biofiber Co., Ltd. and Donghua University"Key technology and industrial application of wool cashmere polylactic acid fiber series fabrics"It has passed the project appraisal organized by China Textile Industry Federation. The expert group composed of China Textile Industry Federation, China Wool Textile Industry Association, Shanghai Textile Science Research Institute, Jiangnan University, Nantong University and other institutions agreed that the technical project focused on the research and development of the preparation technology and equipment of high-strength and soft polylactic acid fiber suitable for wool and cashmere, the two-stage variable speed temperature rise dyeing process of polylactic acid fiber, and the sewing shrinkage of wool and cashmere polylactic acid blended fabric The overall technology of low temperature lustration finishing technology has reached the international advanced level, and has independent intellectual property rights. At the same time, a batch fabric production line has been built, which has made outstanding industrial contributions to the technological innovation, energy conservation and low-carbon development of bio based fibers and degradable materials in the wool textile industry.

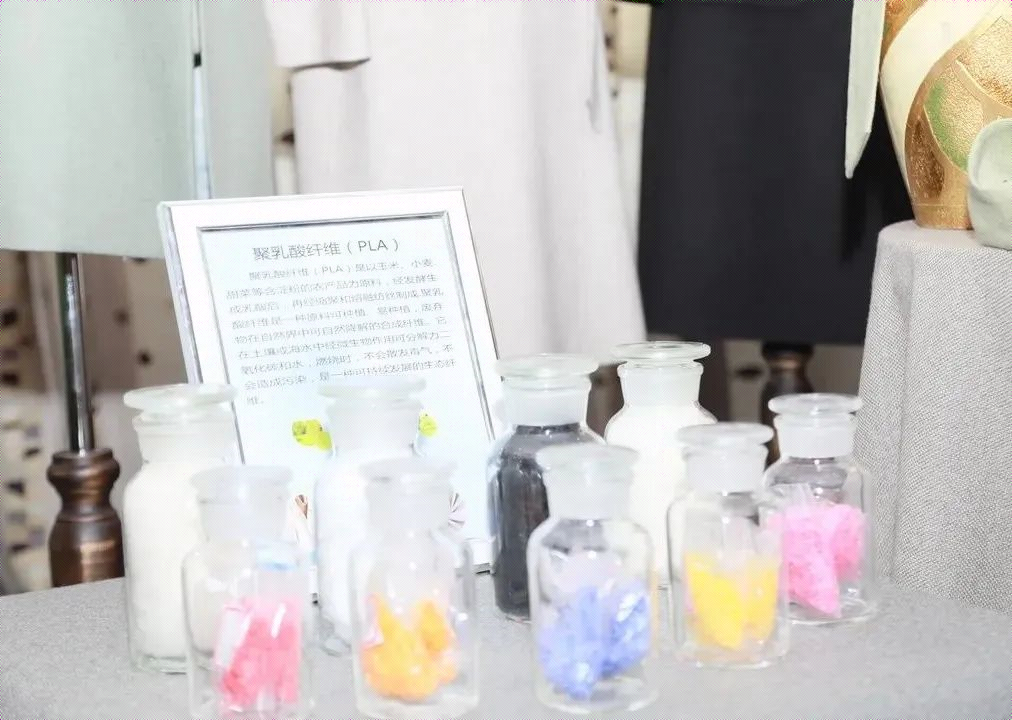

It is reported that,Biological basePLA(Polylactic acid fiber)It has good biodegradability, high strength and UV resistance, and is widely used in the field of textile and clothing. It is made of corn, potato and other starch containing biomass or straw cellulose by using biological fermentation technology and special polymerization process. After use, it can be decomposed into carbon dioxide and water by microorganisms. Through plant photosynthesis, it continues to be the starting material for the production of polylactic acid fiber. It is beneficial to human health and has a good sense of comfort, no stimulation, and it is antibacterial, anti mite, skin friendly and breathable, It is recognized as environmentally friendly material.

However, polylactic acid fiber has low coloring rate, low melting point, and is not resistant to high temperature. Wool and cashmere products need a series of high temperature processes such as washing, boiling, and steaming to show their unique soft waxy smoothness.

The project of "Key Technology and Industrialized Application of Wool Cashmere Polylactic Acid Fiber Series Fabrics" innovatively developed the preparation technology of superfine polylactic acid fiber for wool spinning, the dyeing technology of wool cashmere polylactic acid fiber and the key technology of low-temperature finishing of wool cashmere polylactic acid fiber fabrics, which achieved energy conservation and consumption reduction, improved dye uptake and color fastness, and broke through this "bottleneck" problem.

Gao Qinghua, Deputy General Manager of Jiangsu Sunshine Co., LtdIntroduction: The technical innovation of this project aims to give consideration to the characteristics of wool and cashmere while giving full play to the advantages of polylactic acid fiber. The proportion, dyeing, finishing and other processes of various fibers are optimized and innovated, which not only overcomes the property of polylactic acid that is not resistant to high temperature, but also endows the fabric with soft and natural luster and smooth and soft feel. At the same time, it has the functions of bacteriostasis, acarid suppression, and maintaining complete biodegradability.

The project applies for relevant invention patents13Pieces, authorized4At present, a mass production line of fabrics has been built, which has achieved a breakthrough from the experimental stage to the industrial promotion. The products have the characteristics of green environmental protection, bacteriostatic comfort, good human compatibility, microbial degradation, recycling sustainability, etc., which can meet the consumer's demand for the application of green environmental protection, skin friendly comfort, and long-term bacteriostatic functional textiles, and have played a positive role in promoting the technological innovation and low-carbon development of the entire wool textile industry, It has remarkable economic and social benefits.

Sustainable development has become a global consensus. Jiangsu Sunshine Group, as a practitioner of the concept of green and low-carbon development, takes the "double carbon" goal as the strategic orientation, constantly responds to the people's demands for a better life, shapes new advantages in market competition by strengthening green technology innovation, provides new processes, new technologies, and new products for the green and low-carbon cycle development of industry, and injects source power to achieve high-quality development in harmony with the economy and the environment!